Tapped Apple Part 2

Fermentation Day

The second installment of my multi-part series about the family owned and operated Tapped Apple Cidery and Winery focuses on the fermentation of a batch of Apple Wine at their tasting room.

At the moment, Tapped Apple has five 600 gallon vats set up for fermentation of either Hard Apple Cider or Apple Wine. Two vats are located in their tasting room at — High Street in Westerly, Rhode Island, and the other three are down the road at their warehouse.

Fermentation turned out to be part science and part brute force, along with a heavy dose of patience. The gist of the process involves fresh apple cider, sugar, yeast, heat and time. It was great to watch the father-son team of John IV and John V work together. John V is picking up more knowledge and responsibilities related to various aspects of the business, including the all-important fermentation process.

Tapped Apple only has a few weeks of the year to start the fermentation process for all the product they will be able to sell throughout the next calendar year. They have to predict trends and tastes, and make sure there are enough gallons of each flavor to meet demand.

Preparation

Each batch of cider requires precise measurement of sugar levels and temperature. Once attained, the (secret) recipe for the flavor of Hard Cider or Apple Wine they intend to ferment is calculated and measured out.

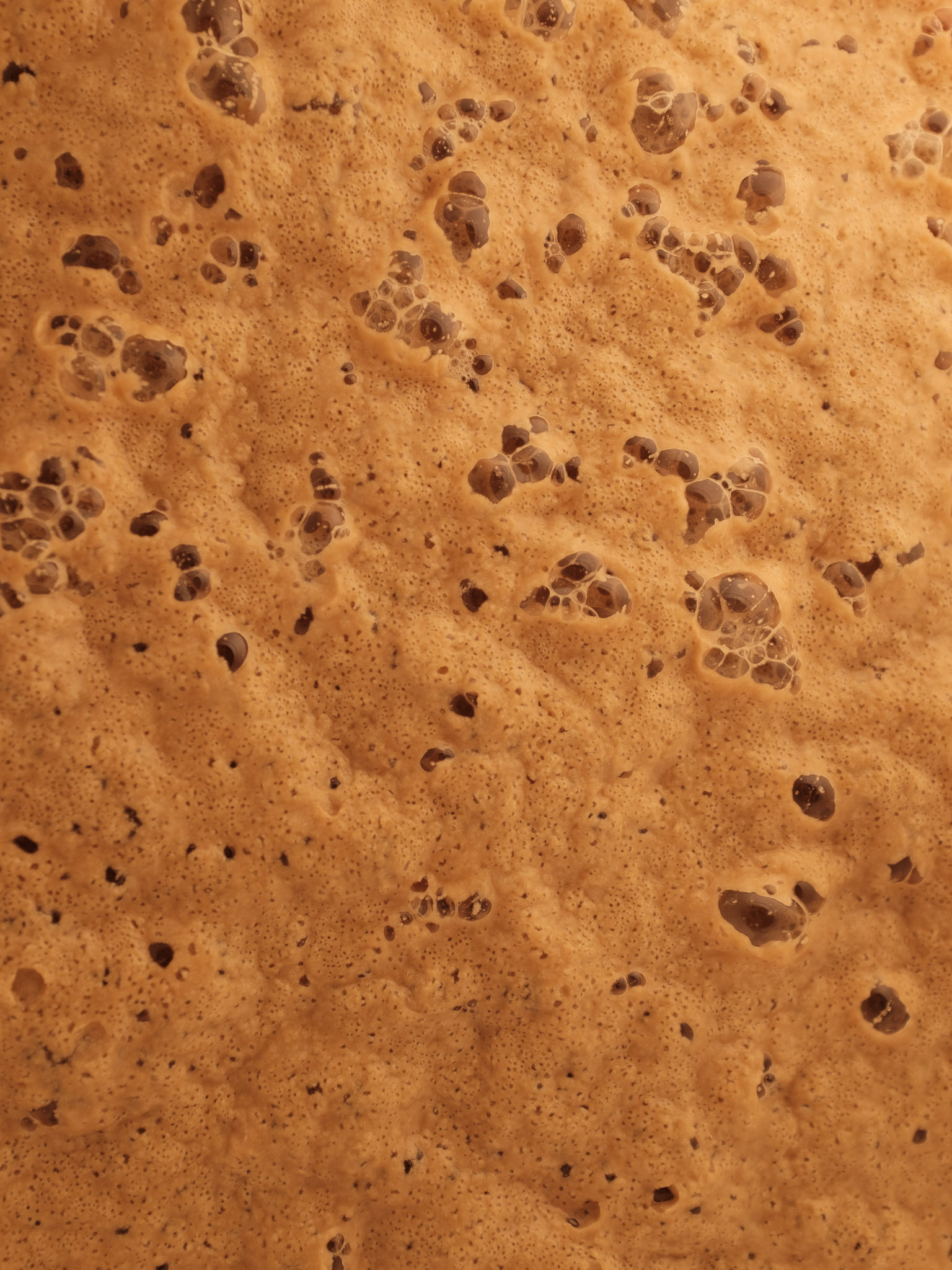

Mix

The flavor additives and sugar are poured into the vats, while the full batch of cider and ingredients is agitated via a pump that cycles the cider from top to bottom. The closed loop system they devised minimizes the loss of product and helps stabilize the fermentation process.

Starter

I think my “Starter” label is something of a misnomer, since it’s the final part of the process. It does “start” the fermentation though as it is comprised of a sample of the cider combined with yeast and yeast nutrient that, once activated, is added back into the full batch of cider. The starter sets the tone for the fermentation that creates their final product and is slowly built up over the course of an hour or so with increasing amounts of warmed cider.

After the starter has reached its intended concentration, John IV adds it back into the full batch and seals off the vat. Nature will take over from here and the cider will ferment over the next 8 to 10 months into the hard apple cider or apple wine they set out to make.

This batch is a wine and will ferment in the tasting room for a few weeks before being moved to their warehouse for the final stages of its fermentation.

Coming up next in this multipart series is canning, in which an ingenious canning system is deployed to can, label and package hundreds of cases of Tapped Apple Cider within a couple hours.

Tapped Apple’s tasting room is located at 37 High Street in Westerly, Rhode Island, and their products are available in restaurants and liquor stores throughout the state.

Andy DelGiudice is a professional photographer that helps people and businesses look their best. He specializes in portraits, headshots, as well as branding and marketing style photography sessions that are ideal for websites, advertising and marketing initiatives.

Send him an email or give him a call if you or your organization want to learn more about how he can help you visually communicate who you are and what you do.